Like a period before conveyance orders consumed a large chunk of the day without any issue of status or any records even with no managemnt , they were all written by hand records , however presently in this cutting edge time of ERP it has made effectively conceivable to deal with this in fingers.Because these days conveyance assumes a significant part in satsfaction of clients.Delivery request the executives is vital for undertakings and relies upon a few elements, for example, distribution center size, item variations, request count, and so on.

ERP based programming Odoo an extremely astounding , effectively adjustable programming with inbuilt stockroom and stock features,ensures organizations’ conveyance orders management.A client utilizing Odoo makes easilty conceivable to make moves, transporting techniques, distribution centers, item variations, recharging, scraps, and something else for an association.

Odoo permits you to deal with delivery from distribution center in 3 distinct ways:

-One step (shipping): ship directly from stock

-Two steps (pick + ship): Bring goods to output location before shipping

-Three steps (pick + pack + ship): Make packages into a dedicated location, then bring them to the output location for shipping.

ONE STEP

For a business profile having a little stock distribution centers that doesn’t need many stock things needs a solitary conveyance process straightforwardly from deal request

as it doesn’t need a great deal of setup and permits to deal with orders rapidly.

Select distribution centers in a setup and tap on make button as demonstrated beneath

- ADD your organization name in warehouse1 and a shortcode to distinguish the stockroom in short name feild.

- Then, at that point, add your organization subtleties and afterward snap to save button

Subsequent to saving the subtleties, you can see a Warehouse Configuration tab that comprises of Resupply and Shippemnt subtleties. The default active courses are noticeable in the Outgoing Shipments field and select Deliver products straightforwardly as referenced in the screen capture underneath. - Presently go to either deals module and make a deal request or go to make deal request from distribution center choice.

- In making deal request add an item to add a product offering tab .

- Subsequent to saving the detail check and affirm the request to make a conveyance.

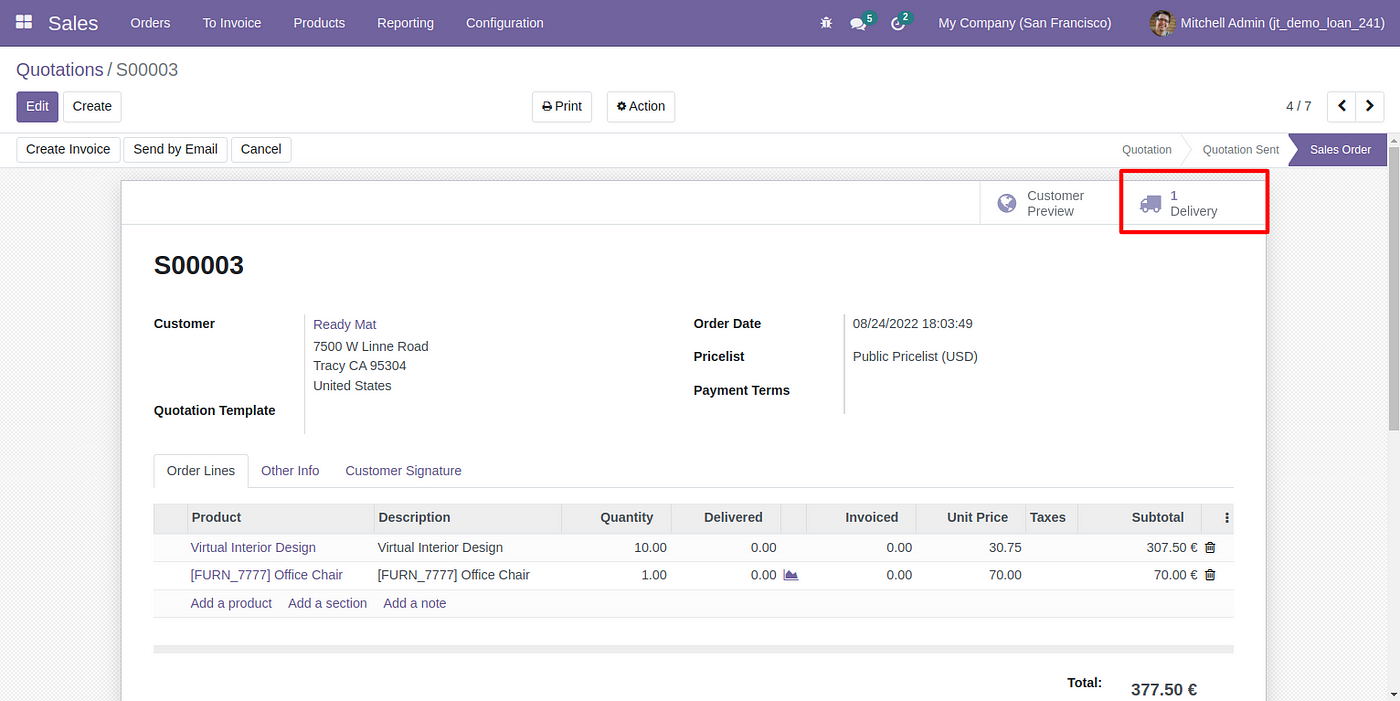

You can see a truck marked conveyance oreder set apart in the receipt , press that symbol and you will be coordinated to a stock page with a checked ‘conveyance request’ tab in kanban view.

Your product transfer is ready for the customer location in the Delivery Orders window.

TWO STEPS

Your company’s business process may have one or more steps that happen before shipping. In the two steps process, the products which are part of the delivery order are picked in the warehouse and brought to an output location before being effectively shipped.

Now before you create the delivery order go to settings in inventory configurations in warehose options Activate ‘multi-step routes’ which will also activate ‘storage locations’.

After you activate multi step route option then enter the waehouse details which you will use in two step delivery process and then you can select Send Goods In Output And Then Deliver (2 Steps) For Outgoing Shipments.

After configuring this will lead to the output create location.Update your output warehouse name if you want

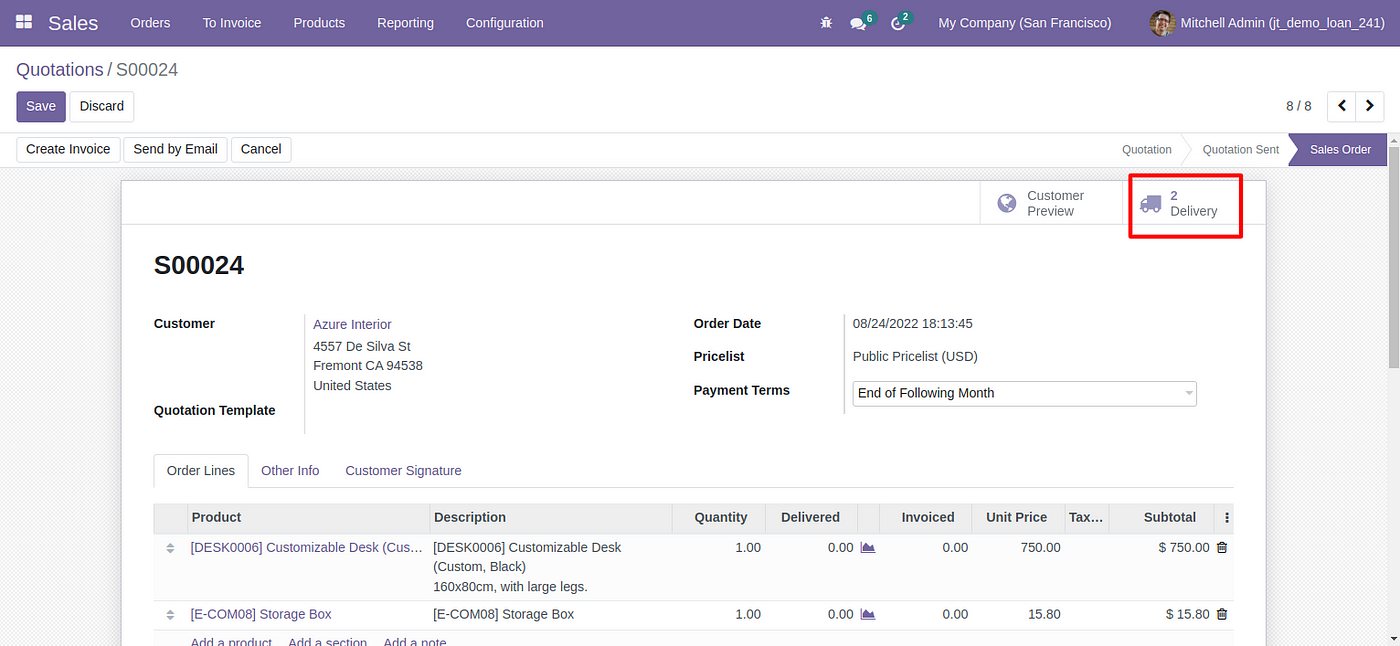

Again follow the same steps to ceate a delivery order, this time two pickings will be created automatically linked to sale order.

Now you can see the two picking options if you click the truck signed delivery option one to pick and one for out to designate the picking process.

The conveyance opto will just prepare once the picking system is finished, make the picking system done maually to produce the conveyance naturally.

THREE STEPS

On the off chance that your organization has an extremely enormous administration of stocks like has many cycles prior to conveying it like the things will be picked to be moved to a pressing region. Then, at that point, they will be moved to a result area prior to being successfully delivered to the clients.

Before creating the delivery or sale order go to cofigurations of inventory and enable multi step ruotes which will also create the storage locations.

On making the capacity areas the page will be coordinated to choose yield stockroom area.

When Multi-Step Routes has been enacted, you can go to Inventory ‣ Configuration ‣ Warehouse and enter the stockroom which will involve conveyance in 3 stages. You can then choose the choice Pack products, send merchandise in result and afterward convey (3 stages) for Outgoing Shipments.

Then follow a similar cycle to make the conveyance request by making the deal request, this time three choices will be seen in pick conveyance choices.

One for pack where you want want the stock to proceed after shipment, then pick where you want the packages of the stock to be picked form to delivery order

This multitude of steps are trailed by individually

Assuming you click the button, you ought to now see three unique pickings:

The first with a reference PICK to assign the picking system,

The second one with the reference PACK that is the pressing system,

The final remaining one with a reference OUT to assign the delivery interaction.

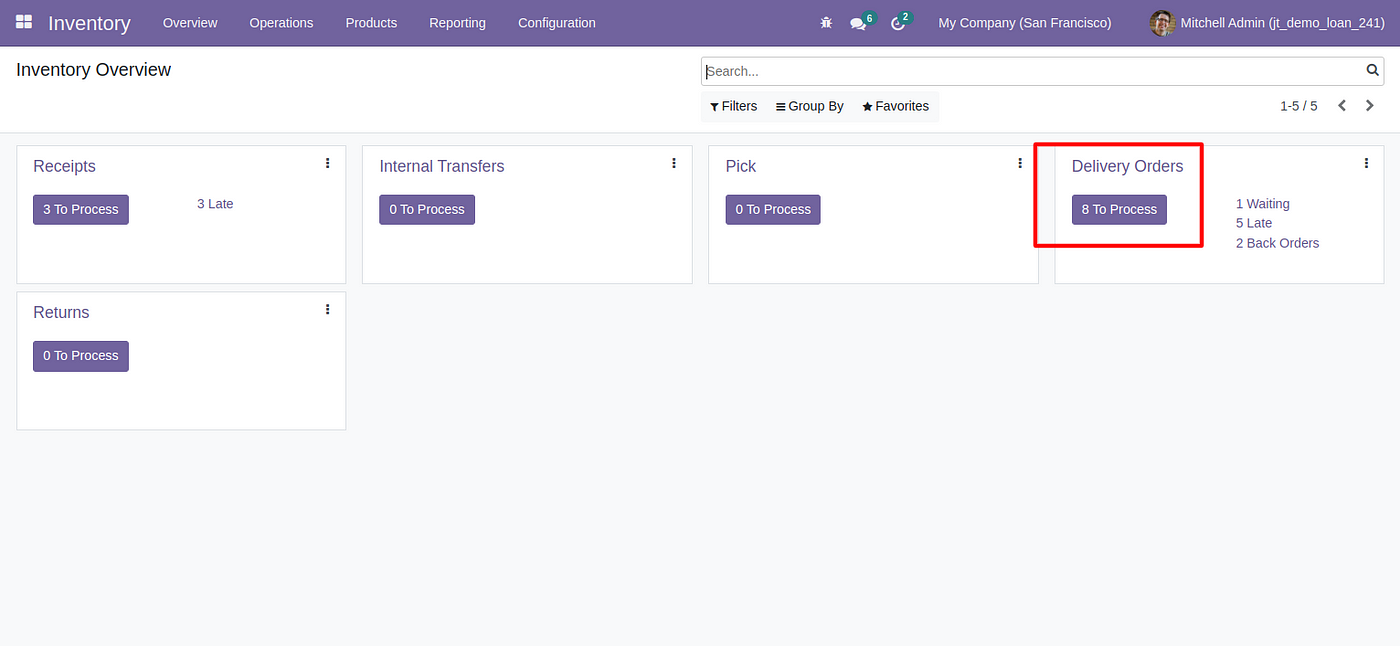

You can make an admittance to your stock dashbord for these pick ,pack and conveyance choices

Individually the means are followed in the event that you approve the pack choice the status will be finished and pick status will prepare.

In the wake of approving the pick otion the status goes to done andthe continue to convey choice.

In convey choice assuming you approve the dilevery processs closes with status ‘done’.